Our Capabilities

Machining Capabilities

KSEC offers extensive machining capabilities across a wide range of materials, including steel of various grades, castings, forgings, non-ferrous materials, and specialized plastics like Cast Nylon 6. Below is an overview of these capabilities:

Steel of Various Grades

- Expertise in machining carbon steel, alloy steel, stainless steel, and tool steel.

- Capable of handling high-precision machining for complex components.

- Equipped for processes such as turning, milling, drilling, boring, and grinding to meet tight tolerances and surface finish requirements.

Forgings and Castings

- Machining capabilities extend to forged components made from steel, aluminium, and other alloys.

- Expertise in handling high-strength materials, ensuring durability and precision in final products.

- Processes tailored for components requiring high mechanical strength and fatigue resistance.

Non-Ferrous Materials

- Proficient in machining aluminium, copper, brass, and other non-ferrous metals.

- Focus on lightweight and corrosion-resistant applications for industries like electrical, automotive, and aerospace.

- Advanced techniques to maintain material integrity and achieve superior finishes.

Plastics, Including Cast Nylon 6

- Specialization in machining engineering plastics, with a focus on Cast Nylon 6.

- Capable of producing lightweight, wear-resistant, and low-friction components ideal for industrial applications.

- Expertise in maintaining thermal stability and dimensional accuracy during machining processes.

KSEC's machining capabilities are designed to handle a diverse range of materials, from high-strength steels and alloys to lightweight non-ferrous metals and engineering plastics. With advanced equipment and skilled personnel, the company ensures precision, quality, and reliability in every component it manufactures, catering to the needs of industries worldwide.

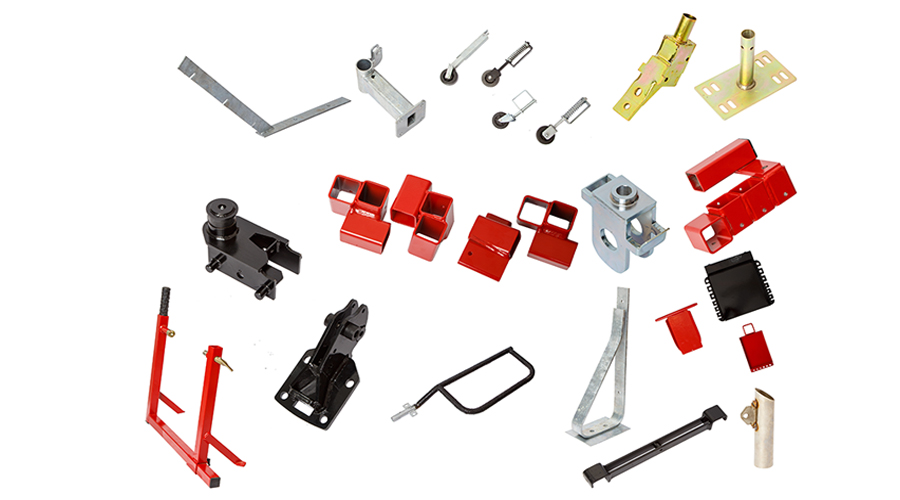

Fabrication Processes

- Cutting: Equipped with advanced CNC laser cutting, plasma cutting, and waterjet cutting machines for precise and efficient material cutting.

- Welding: Expertise in various welding techniques, including MIG, TIG, arc, and spot welding, ensuring strong and reliablejoints.

- Forming and Bending: Modern press brakes and rolling machines for accurate forming, bending, and shaping of metals.

- Machining Integration: Seamless integration of machining processes for components requiring both fabrication and precision machining.

- Surface Treatment: Capability to provide surface finishing, including painting, powder coating, galvanizing, and polishing, for enhanced durability and aesthetics.

Custom Fabrication

- Ability to fabricate bespoke components and assemblies tailored to specific customer requirements.

- Expertise in producing complex structures, frames, enclosures, and industrial equipment.

- Focus on delivering solutions for industries such as automotive, construction, heavy machinery, and energy.

ISO 9001:2015

TUV NORD CERT GmbH Certificate Registration No.44 100 23394617